WTNT

Features:

l Servo Amplifier and Servo motor control, accuracy far over exceed the use of traditional inverter control.

l Main drives are control separately by two servo amplifier and servo motors.

l Machine is manufacture completely from Japanese drawings.

l Main electrical components are completely ship from Japan.

l Chain running speed can run up to maximum of 150m/min.

l Each chamber equipped with individual motor for width adjustment.

l Heat source choices are high pressurized steam, LNG or LPG, and Thermo Oil

l Market successfully over 10 years.

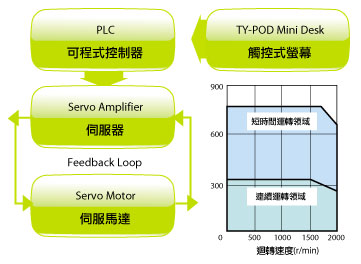

POWER OF SERVO AMPLIFIER

l High resolution feedback system, allowing instantaneous monitoring of servo motor’s status

l Full torque action under low speed condition, allowing instantaneous reaction for anticipated request

l Extreme precision and accuracy

l Control directly thru PLC internal system, eliminates disturbance

HOT AIR CHAMBER

l Each hot air chamber is design to stop all fan motors in few seconds to protect the fabric when the machine is stop. This is standard and is programmed by PLC.

l Two high efficient Centrifugal “Turbo” fans are installed in each chamber for smooth and high air circulation. Each motor is controlled by AC inverter drive for infinite variable speed, and the amount of hot air circulated inside the chamber can be set easily at the POD.

l Adjusting the individual damper can regulate the volume of air circulated through the upper and lower nozzles in each chamber.

l The velocity of airflow inside the chamber is computer control to within ±10%, and the temperature variation to within ±2°C.

l Each exhaust fan is controlled by AC inverter drive for variable speed control. Optimum speed can be obtained easily by setting at the POD to cut down heat loss and reduce energy consumption.

l Heat source choices can be high pressurized steam, LNG or LPG, and Thermo Oil.

Double Main Drive System

Main drive is control by servo amplifier and servo motor on each

side. This gives a better flexibility on the fabric processing and

maintenance is easy.

Machine Data

|

CHAMBER |

MACHINE LWNGTH mm |

DRIVING SERVOMOTOR |

CIRCULATING FAN MOTOR |

HEATER ELEC. GAS.OIL |

HEAT EXCHANCE X10,000 kcal/hr |

||

|

J |

L |

TL |

|||||

|

4 |

12000 |

19000 |

28460 |

5X2 |

8 sets |

4 sets |

68 |

|

5 |

15000 |

22000 |

31460 |

5X2 |

10 sets |

5 sets |

85 |

|

6 |

18000 |

25000 |

34460 |

7.5X2 |

12 sets |

6 sets |

102 |

|

7 |

21000 |

28000 |

37460 |

7.5X2 |

14 sets |

7 sets |

119 |

|

8 |

24000 |

31000 |

40460 |

11X2 |

16 sets |

8 sets |

136 |

|

9 |

27000 |

34000 |

43460 |

11X2 |

18 sets |

9 sets |

153 |

|

10 |

30000 |

37000 |

46460 |

11x2 |

20 sets |

10 sets |

170 |

|

WORKING WIDTH |

MACHINE LWNGTH mm |

||||||||

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

|

|

2000 |

2580 |

2200 |

3400 |

2000 |

5450 |

3620 |

2200 |

2690 |

3250 |

|

2300 |

2885 |

2500 |

3700 |

2300 |

5750 |

3920 |

2500 |

2990 |

3550 |

|

2500 |

2085 |

2700 |

3900 |

2500 |

5950 |

4120 |

2700 |

3190 |

3750 |

|

2800 |

3385 |

3000 |

4200 |

2800 |

6250 |

4420 |

3000 |

3490 |

4050 |

|

3000 |

3585 |

3200 |

4400 |

3000 |

6450 |

4620 |

3200 |

3690 |

4250 |

Standard electric equipment

|

PARTS |

MAKERS |

COUNTRY OF ORIGIN |

|

A. TOUCH SCREEN PANEL |

FUJI |

JAPAN |

|

B. SERVO AMPLIFIERS |

TOEI |

JAPAN |

|

C. SERVO MOTORS |

TOEI |

JAPAN |

|

D. PLC CENTRAL CONTROL |

FUJI |

JAPAN |

|

E. INVERTERS |

FUJI |

JAPAN |

|

F. AC MOTORS |

TECO |

TAIWAN |

|

G. THERMO CONTROLLER |

YAMATAKE |

JAPAN |

|

H. RELAY AND BREAKERS |

FUJI |

JAPAN |