TMW

Features:

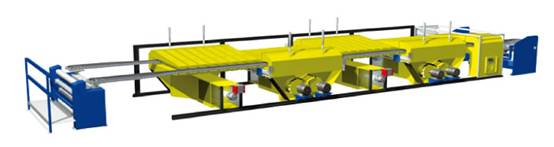

l Unique vertical rail design especially for processing knit fabrics.

l Machine is manufacture completely from American drawings.

l Dual Air Circulation System

l Large side door to be accessible for easy and efficient maintenance.

l Heat source choices are high pressurized steam, LNG or LPG, and Thermo Oil

l Highly humanized chamber design, allowing fully large side door to be accessible for easy and efficient maintenance.

l Two centrifugal fans on each chamber.

l Each chamber is 3 meters long

l Heat source can equipt with Thermo oil, LPG or LNG and High Pressurized Steam

l Extreme productivity and energy efficient

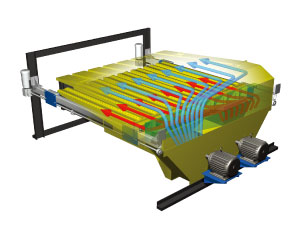

Dual Air Circulation

The upper and lower air of each chamber is control separately by

individual fan, which are then control by inverter. This design

allows more flexibility in the fabric processing.

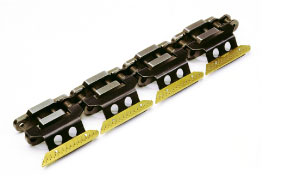

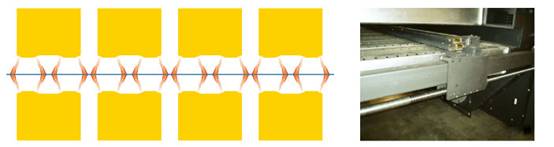

Nozzles System

Special nozzle design allowing virtually all kinds of efficient

fabric processing

Machine Data

Main Specification

|

Working Width |

Machine Width(mm) |

||||||||

|

A |

B |

C |

D |

E |

E' |

F |

G |

H |

|

|

2000 |

2565 |

2200 |

4050 |

2000 |

4050 |

5200 |

2200 |

2690 |

3200 |

|

2200 |

2765 |

2400 |

4250 |

2200 |

4250 |

5400 |

2400 |

2890 |

3400 |

|

2400 |

2965 |

2600 |

4450 |

2400 |

4450 |

5600 |

2600 |

3090 |

3600 |

|

2600 |

3165 |

2800 |

4650 |

2600 |

4650 |

5800 |

2800 |

3290 |

3800 |

|

2800 |

3365 |

3000 |

4850 |

2800 |

4850 |

6000 |

3000 |

3490 |

4000 |

|

3000 |

3565 |

3200 |

5050 |

3000 |

5050 |

6200 |

3200 |

3690 |

4200 |

|

3200 |

3765 |

3400 |

5250 |

3200 |

5250 |

6400 |

6400 |

3890 |

4400 |

Power Consumption (mm)

|

Chambers |

Machine Length(mm) |

Machine Length(mm) |

Driving Motor |

循環風扇 |

熱交換器 |

熱交換量 |

|||||

|

C.L |

R.L1 |

T.L1 |

C.L |

R.L2 |

T.L2 |

HP |

KW |

Circulating Fan Motor |

Heater Elec.Gas. Oil |

X10000 Koal/Hr |

|

|

4 |

12000 |

21600 |

30200 |

12000 |

20100 |

28700 |

15 |

11 |

8 sets |

4 sets |

68 |

|

5 |

15000 |

24600 |

33200 |

15000 |

23100 |

31700 |

20 |

15 |

10 sets |

5 sets |

85 |

|

6 |

18000 |

27600 |

36200 |

18000 |

26100 |

34700 |

20 |

15 |

12 sets |

6 sets |

102 |

|

7 |

21000 |

30600 |

39200 |

21000 |

29100 |

37700 |

25 |

18.5 |

14 sets |

7 sets |

119 |

|

8 |

24000 |

33600 |

42200 |

24000 |

32100 |

40700 |

30 |

22 |

16 sets |

8 sets |

136 |

|

9 |

27000 |

36600 |

45200 |

27000 |

35100 |

43700 |

40 |

30 |

18 sets |

9 sets |

153 |

|

10 |

30000 |

39600 |

48200 |

30000 |

38100 |

46700 |

40 |

30 |

20 sets |

10 sets |

170 |

Dryer Performance

|

Material |

Process |

Material Weight |

Width meters |

Speed m/m |

Meters per day required |

Hours per day required |

Kilograms per day |

|

lycra |

Dry & HS 190 degC for 45 seconds |

300 |

1.8 |

21.7 |

10,000 |

7.7 |

5,400 |

|

cotton |

Dry 70% to 5% |

100 |

1.8 |

142.5 |

20,000 |

2.3 |

1,000 |

|

cotton |

Dry 70% to 5% |

175 |

1.8 |

109 |

10,000 |

1.5 |

3,150 |

|

P/C |

Dry & HS 180 degC for 5 seconds |

300 |

1.8 |

53.2 |

20,000 |

6.3 |

10,800 |

|

|

Total |

60,000 |

17.8 |

20,350 |

|||

|

Material |

Process |

Speed m/m |

Meters per day required |

Kilograms per day required |

Thermal Energy Consumption |

Electrical Energy Consumption |

||||

|

Connected kCal/hr |

Operating kCal/hr |

Kcal per kg |

Connected kW |

Operating kW |

kW-hr per kg |

|||||

|

lycra |

Dry & HS 190 degC for 45 seconds |

21.7 |

10,000 |

5,000 |

2,016,000 |

869,000 |

1,236 |

180 |

65 |

0.0925 |

|

cotton |

Dry 70% to 5% |

142.5 |

20,000 |

1,000 |

1,460,000 |

949 |

125 |

0.0812 |

||

|

cotton |

Dry 70% to 5% |

109 |

10,000 |

3,150 |

1,231,000 |

598 |

125 |

0.0607 |

||

|

P/C |

Dry & HS 180 degC for 5 seconds |

53.2 |

20,000 |

10,800 |

1,253,000 |

727 |

112 |

0.0650 |

||

|

|

Total |

60,000 |

20,350 |

|

||||||

Standard electric equipment

|

PARTS |

MAKERS |

COUNTRY OF ORIGIN |

|

A. TOUCH SCREEN PANEL |

FUJI |

JAPAN |

|

B. PLC CENTRAL CONTROL |

MITSUBISHI |

JAPAN |

|

C. INVERTERS |

FUJI |

JAPAN |

|

D. AC MOTORS |

TECO |

TAIWAN |

|

E. THERMO CONTROLLER |

YAMATAKE |

JAPAN |

|

F. RELAY AND BREAKERS |

FUJI |

JAPAN |