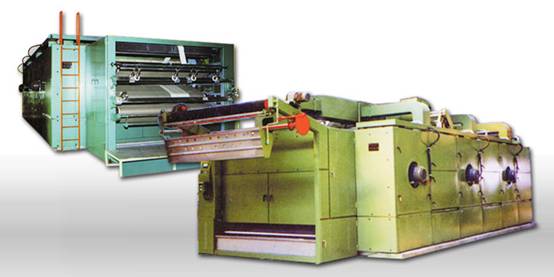

NSD

Features:

l One Axial “Hi-Air” Fans with inverter per chamber

l Individual speed control on each conveyor layer (Patented)

l Conveyor net is made of Nomex or Kevlar Teflon coating glass fiber

l Control by PLC for automatic conveyor net centering

l Heat conservation chamber design (Patented)

l Zig zag nozzle design G. Heat source choices are high pressurized steam, LNG or LPG, and Thermo Oil

l Market successful over 30 years

NOZZLES SYSTEM

l JAPANESE HIRANO DESIGN

l AIR VELOCITIES FROM LEFT TO RIGHT IS WITHING +/- 10% DIFFERENCE TEMPERATURE FROM LEFT TO RIGHT IS ONLY +/- 2 °C

l BALANCE AIR DISTRIBUTION OVERALL

Heat Conservation Chamber

The NSD is specially design with 3 layers of conveyors, each layer

with different drying features:

l When the fabric enters the 1st layer conveyor, the surface temperature starts from 35°C and increase gradually as it moves along. Since the humidity is low at the 1st layer since the temperature has not reach the evaporation point, no exhausting action will be done on the 1st layer, to preserve heat and segregate from the 2nd layer.

l When the fabric enters the 2nd layer, the surface temperature is reached to evaporation point. The newly design exhausting system will only exhaust this 2nd layer humidity without effecting the other layers. This will greatly increase the heat efficiency of NSD and avoid unnecessary heat lost by the exhausting action.

l When the fabric reaches the 3rd layer, the drying process is almost done. The water content in the fabric is low and the air temperature at the 3rd layer is higher than the above layers. All the hot air in the 3rd layer will be recycled back immediately to the heat exchanger for great heat usage.

Machine Data

|

WORKING WIDTH |

|||

|

WORKING |

CONVEYOR |

ROLLER |

BODY |

|

1800 |

1900 |

2000 |

D=4140 |

|

2000 |

2100 |

2200 |

D=4340 |

|

2200 |

2300 |

2400 |

D=4540 |

|

2300 |

2400 |

2500 |

D=4640 |

|

2400 |

2500 |

2600 |

D=4740 |

|

2500 |

2600 |

2700 |

D=4840 |

|

2600 |

2700 |

2800 |

D=4940 |

|

3000 |

3100 |

3200 |

D=5340 |

|

WORKING TEMP & HEAT SOURCE |

|

|

HEAT SOURCE |

WORKING TEMP |

|

LPG or LNG |

220°C MAX |

|

THERMO OIL |

220°C MAX |

|

STEAM |

6KG/CM2 130°C MAX |

|

ELECTRIC |

220°C MAX |

|

CHAMBER |

C |

L |

MAX SPEED |

FAN MOTOR |

|

2 |

3000 |

5580 |

20 m/min |

C = 40hp / cl |

|

3 |

4500 |

7080 |

30 m/min |

C = 60hp / cl |

|

4 |

6000 |

8580 |

60 m/min |

C = 80hp cl |

|

5 |

7500 |

10080 |

60 m/min |

C =100hp cl |

|

6 |

9000 |

11580 |

60 m/min |

C = 120hp cl |

|

7 |

10500 |

13080 |

60 m/min |

C = 140hp cl |

|

8 |

12000 |

14580 |

60 m/min |

C = 160hp cl |

|

PARTS |

MAKERS |

COUNTRY OF ORIGIN |

|

A. TOUCH SCREEN PANEL |

FUJI |

JAPAN |

|

B. PLC CENTRAL CONTROL |

OMRON |

JAPAN |

|

C. INVERTERS |

FUJI |

JAPAN |

|

D. AC MOTORS |

TECO |

TAIWAN |

|

E. THERMO CONTROLLER |

YAMATAKE |

JAPAN |

|

F. RELAY AND BREAKERS |

FUJI |

JAPAN |